Pipe relining is a long-lasting and proven drain repair technology with costs starting from $500 to $800 per metre. Additional and multiple cost factors are important considerations when weighing up your repair options.

Often significantly more cost-effective than ‘Dig to Discover’ repair methods, pipe relining works by inserting an environmentally friendly epoxy liner, impregnated with resin, into the defective pipe, cured in place using pressurised air (and hot water) to fix existing issues and eliminate the risks of joining old pipes with new. Proven to provide long-lasting repairs that work well for residential homes and as well as commercial facilities, pipe relining can restore:-

- Pipes within buildings, as well as underground and under building foundations

- Domestic and commercial vertical drains, roof drains, storm and sanitary drains

- Systems with multiple bends, elbows, branches and transitions

- All types of pipe including clay, concrete, metal, iron, steel, PVC and fibreglass

Provided the ability to use an existing access point(s), good technicians can complete repairs without the need to dig and selecting the right team of licensed and insured technicians will minimise hazards to people, ensure home, work and commercial spaces remain operational and provide peace of mind with a full guarantee on the installation work.

Pipe & Drain Problems

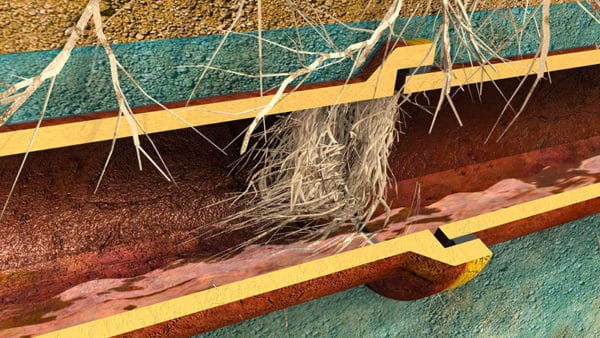

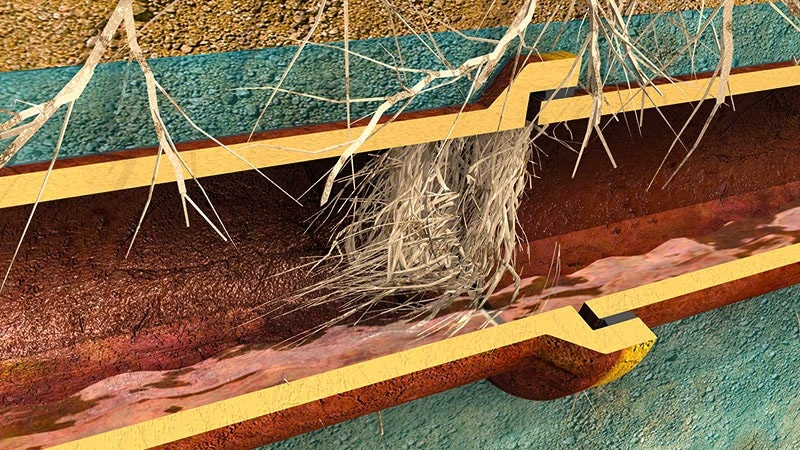

Degradation is a natural and inevitable process of aging plumbing and drainage systems, yet even modern systems experience problems. From structural failure to copper pinhole leaks caused by excessive chlorine exposure, to corroded galvanised pipes and root intrusion causing cracked and broken pipes and blocked drains. Common indications that your plumbing may have a problem can include:

- Coloured, bad tasting and foul-smelling drinking water

- Poor water flow

- Water not draining or rising from showers and sinks

- Poor water flow

- Visible mould and mildew

- Bad smell drains

- Pooling water at ground level, especially evident during rain

When a pipe or drain needs to be repaired or replaced, the traditional method has been to excavate the surrounding area to provide the plumbing team physical access to remove the damaged pipe and replace it with new sections. If the drain requiring repair is under your lawn or garden, the traditional dig method may sometimes be cheaper, it does, however, cause damage to the landscape and even the best joins between old and new pipe can (all too soon) be prone to leaking.

Unfortunately, when problems exist under a solid structure such as your footpath, driveway or shed, the cost of the ‘dig’ method can increase significantly as structural repairs are factored in. In such cases, we would recommend one or a combination of the following pipe relining solutions without which the situation will only become more expensive to repair as:

- Tree root growth will continue to enter, creating increasingly frequent issues.

- Wastewater escapes out of loose joins and cracks, washing away the surrounding bed, causing the pipe to collapse.

- Sewage smell emanates from within the ground, causing foul stenches.

- Surrounding dirt and earth seeps into pipes through holes and cracks causing constant blockages and the ground to subside.

High-Pressure Water Cleaning

High-pressure water cleaning is ideal for shifting debris and substances found within, around or attached to a drain, sewer or process pipe. Capable of breaking up everything from rust and scale to resins, chemical residue and paint, concrete and rubble high-pressure water jetting is a fast and effective means to remove build-up and blockages resulting in an as new pipe system with optimum flow. This prepares the pipes for CCTV Inspection.

CCTV Drain Inspections

Once cleaned, a CCTV survey camera is used to locate and identify issues by reaching normally inaccessible areas to reveal issues in your drainage system. Left unaddressed cracked and broken pipes lead to recurring leaks and blockages, gradual build-ups of blockages and serious structural problems. The CCTV drain inspection provides your plumber information to diagnose the issue and advise you on your best repair options.

Pipe Relining Solutions

Pipe Patching for Sectional Repairs

Sectional pipe patching is an effective, affordable option best suited for smaller targeted sections of pipework. From a single access point, pipes interiors are cleaned and dried then a poly woven soft liner impregnated with epoxy. An inflatable bladder is inserted into the soft liner, and the pair are positioned inside the pipe. Once in place, the bladder is inflated so that the liner and epoxy resin is pressed tight and bonds to the inner wall of the pipe or drain. Once the bladder is deflated and removed, and the epoxy liner has cured, your pipes are free of corrosion, clogs, and tree roots cannot force their way through the pipes. Most jobs require only one or two days to complete requiring minimal disruption to daily routines. Benefits include:

- Improved flow rate

- Structurally sound pipes

- No groundwater contamination

- No tree root invasion

Junction Patching for Sectional Repairs

Defective junctions and connections have been at the top of the list of drainage issues for decades, and it’s not just a problem for older systems; incorrectly fitted junctions and connections are also seen in new systems. Improper fitting of the post lining, constriction of the materials during the curing process or a lack of resistance against aggressive sewage can all lead to the rehabilitated connections not being watertight. Junction Patching is generally required when the floor or walls show signs of damp or start to produce mould or saltpetre. Benefits include:

- custom-fit and tight-fitting

- epoxy resin provides optimum bonding with existing pipes

- no restriction to flows

- high durability against chemicals

Robotic Cutting

With an integrated colour camera, air and water cleaning, robotic cutting equipment provide flexible, reliable precision and efficiency and excellent manoeuvrability in pipes from 50mm to 250mm in diameter – even through 90-degree bends. Used to cut, grind and mill intrusions, encrustations and damaged liners, grout filled pipes and even completely blocked sewers due to tree roots, debris and concrete. They are useful for preparing pipes and drains for the relining process. Once relining repairs are complete, robotic units can also be deployed to reopen lateral connections in the relined pipes.

Inversion Pipe Relining

Inversion pipe relining is best for long lengths of pipework that require one continuous length of liner. The four-step process begins with 1) mixing of an epoxy and silicate resin. A long length of the liner is then 2) filled with the resin mixture using a roller 3) the liner is placed in a pressurised inversion drum, which turns the liner inside out and forces the epoxy filled liner through a nozzle into the pipe. The epoxy filled liner is then 4) hardened using a combination of compressed air and hot water to create a new rock-solid, surface inside your old pipe with a 50-year life expectancy and installation guarantee.

How Much Does Pipe Relining Cost?

Pipe relining costs start from $500 to $800 per meter yet in every case a site visit is required to provide an accurate estimate. Key cost variables include:

- Relining material

- Labour time

- Ease of access to the pipes, which may involve a small amount of cutting or digging

- Location of the damage relative to access

- The material your pipe is made out of

- Length of damaged pipework

- The diameter of damaged pipework

- How many breaks and their lengths

- Re-building pipe connections after relining in PVC pipes

When weighing up your options for pipe repairs, remember to factor in the following cost and quality benefits:

- Reduced Expense: Requiring little to no impact to property pipe relining, minimises the cost to repair or replace built structures, surrounding landscapes and hardscapes.

- Cost-Effective: Repairs are generally completed in far less time than the old ‘Dig to Discover’ method, saving labour and subsequently money.

- Less Disruption: Generally, one point of access is all that is required to find, clear, and fix the damaged pipes.

- No Mess: Avoid the inconvenience of having to put up with mess everywhere in your property.

- Futureproof: Even where the pipe is missing the new epoxy piping creates a solid, seamless, smooth barrier and fits to all the cracks and lines of the old pipe to prevent leaks and future root intrusion.

- Improved Water Flow: Pipe Relining increases the water flow inside the pipe as the smooth surface reduces friction compared to clay and cast-iron pipes.

- Peace of Mind: Pipe Relining is a long-lasting solution which should include both manufactures and workmanship guarantees.

The insured, licenced plumbing team at Ruttley Relining provide pipe relining Sydney wide. We’ll need to complete a full assessment of the issue before confirming a price for your job, and we’ll always give you complete costs details before any work begins. With our proven method of pipe relining we guarantee our workmanship for 50 years, and we offer interest-free finance to allow you to get repairs fixed now before disaster strikes.

Pipe relining is a long-lasting and proven drain repair technology with costs starting from $500 to $800 per metre. Additional and multiple cost factors are important considerations when weighing up your repair options.

Often significantly more cost-effective than ‘Dig to Discover’ repair methods, pipe relining works by inserting an environmentally friendly epoxy liner, impregnated with resin, into the defective pipe, cured in place using pressurised air (and hot water) to fix existing issues and eliminate the risks of joining old pipes with new. Proven to provide long-lasting repairs that work well for residential homes and as well as commercial facilities, pipe relining can restore:-

- Pipes within buildings, as well as underground and under building foundations

- Domestic and commercial vertical drains, roof drains, storm and sanitary drains

- Systems with multiple bends, elbows, branches and transitions

- All types of pipe including clay, concrete, metal, iron, steel, PVC and fibreglass

Provided the ability to use an existing access point(s), good technicians can complete repairs without the need to dig and selecting the right team of licensed and insured technicians will minimise hazards to people, ensure home, work and commercial spaces remain operational and provide peace of mind with a full guarantee on the installation work.

Pipe & Drain Problems

Degradation is a natural and inevitable process of aging plumbing and drainage systems, yet even modern systems experience problems. From structural failure to copper pinhole leaks caused by excessive chlorine exposure, to corroded galvanised pipes and root intrusion causing cracked and broken pipes and blocked drains. Common indications that your plumbing may have a problem can include:

- Coloured, bad tasting and foul-smelling drinking water

- Poor water flow

- Water not draining or rising from showers and sinks

- Poor water flow

- Visible mould and mildew

- Bad smell drains

- Pooling water at ground level, especially evident during rain

When a pipe or drain needs to be repaired or replaced, the traditional method has been to excavate the surrounding area to provide the plumbing team physical access to remove the damaged pipe and replace it with new sections. If the drain requiring repair is under your lawn or garden, the traditional dig method may sometimes be cheaper, it does, however, cause damage to the landscape and even the best joins between old and new pipe can (all too soon) be prone to leaking.

Unfortunately, when problems exist under a solid structure such as your footpath, driveway or shed, the cost of the ‘dig’ method can increase significantly as structural repairs are factored in. In such cases, we would recommend one or a combination of the following pipe relining solutions without which the situation will only become more expensive to repair as:

- Tree root growth will continue to enter, creating increasingly frequent issues.

- Wastewater escapes out of loose joins and cracks, washing away the surrounding bed, causing the pipe to collapse.

- Sewage smell emanates from within the ground, causing foul stenches.

- Surrounding dirt and earth seeps into pipes through holes and cracks causing constant blockages and the ground to subside.

High-Pressure Water Cleaning

High-pressure water cleaning is ideal for shifting debris and substances found within, around or attached to a drain, sewer or process pipe. Capable of breaking up everything from rust and scale to resins, chemical residue and paint, concrete and rubble high-pressure water jetting is a fast and effective means to remove build-up and blockages resulting in an as new pipe system with optimum flow. This prepares the pipes for CCTV Inspection.

CCTV Drain Inspections

Once cleaned, a CCTV survey camera is used to locate and identify issues by reaching normally inaccessible areas to reveal issues in your drainage system. Left unaddressed cracked and broken pipes lead to recurring leaks and blockages, gradual build-ups of blockages and serious structural problems. The CCTV drain inspection provides your plumber information to diagnose the issue and advise you on your best repair options.

Pipe Relining Solutions

Pipe Patching for Sectional Repairs

Sectional pipe patching is an effective, affordable option best suited for smaller targeted sections of pipework. From a single access point, pipes interiors are cleaned and dried then a poly woven soft liner impregnated with epoxy. An inflatable bladder is inserted into the soft liner, and the pair are positioned inside the pipe. Once in place, the bladder is inflated so that the liner and epoxy resin is pressed tight and bonds to the inner wall of the pipe or drain. Once the bladder is deflated and removed, and the epoxy liner has cured, your pipes are free of corrosion, clogs, and tree roots cannot force their way through the pipes. Most jobs require only one or two days to complete requiring minimal disruption to daily routines. Benefits include:

- Improved flow rate

- Structurally sound pipes

- No groundwater contamination

- No tree root invasion

Junction Patching for Sectional Repairs

Defective junctions and connections have been at the top of the list of drainage issues for decades, and it’s not just a problem for older systems; incorrectly fitted junctions and connections are also seen in new systems. Improper fitting of the post lining, constriction of the materials during the curing process or a lack of resistance against aggressive sewage can all lead to the rehabilitated connections not being watertight. Junction Patching is generally required when the floor or walls show signs of damp or start to produce mould or saltpetre. Benefits include:

- custom-fit and tight-fitting

- epoxy resin provides optimum bonding with existing pipes

- no restriction to flows

- high durability against chemicals

Robotic Cutting

With an integrated colour camera, air and water cleaning, robotic cutting equipment provide flexible, reliable precision and efficiency and excellent manoeuvrability in pipes from 50mm to 250mm in diameter – even through 90-degree bends. Used to cut, grind and mill intrusions, encrustations and damaged liners, grout filled pipes and even completely blocked sewers due to tree roots, debris and concrete. They are useful for preparing pipes and drains for the relining process. Once relining repairs are complete, robotic units can also be deployed to reopen lateral connections in the relined pipes.

Inversion Pipe Relining

Inversion pipe relining is best for long lengths of pipework that require one continuous length of liner. The four-step process begins with 1) mixing of an epoxy and silicate resin. A long length of the liner is then 2) filled with the resin mixture using a roller 3) the liner is placed in a pressurised inversion drum, which turns the liner inside out and forces the epoxy filled liner through a nozzle into the pipe. The epoxy filled liner is then 4) hardened using a combination of compressed air and hot water to create a new rock-solid, surface inside your old pipe with a 50-year life expectancy and installation guarantee.

How Much Does Pipe Relining Cost?

Pipe relining costs start from $500 to $800 per meter yet in every case a site visit is required to provide an accurate estimate. Key cost variables include:

- Relining material

- Labour time

- Ease of access to the pipes, which may involve a small amount of cutting or digging

- Location of the damage relative to access

- The material your pipe is made out of

- Length of damaged pipework

- The diameter of damaged pipework

- How many breaks and their lengths

- Re-building pipe connections after relining in PVC pipes

When weighing up your options for pipe repairs, remember to factor in the following cost and quality benefits:

- Reduced Expense: Requiring little to no impact to property pipe relining, minimises the cost to repair or replace built structures, surrounding landscapes and hardscapes.

- Cost-Effective: Repairs are generally completed in far less time than the old ‘Dig to Discover’ method, saving labour and subsequently money.

- Less Disruption: Generally, one point of access is all that is required to find, clear, and fix the damaged pipes.

- No Mess: Avoid the inconvenience of having to put up with mess everywhere in your property.

- Futureproof: Even where the pipe is missing the new epoxy piping creates a solid, seamless, smooth barrier and fits to all the cracks and lines of the old pipe to prevent leaks and future root intrusion.

- Improved Water Flow: Pipe Relining increases the water flow inside the pipe as the smooth surface reduces friction compared to clay and cast-iron pipes.

- Peace of Mind: Pipe Relining is a long-lasting solution which should include both manufactures and workmanship guarantees.

The insured, licenced plumbing team at Ruttley Relining provide pipe relining Sydney wide. We’ll need to complete a full assessment of the issue before confirming a price for your job, and we’ll always give you complete costs details before any work begins. With our proven method of pipe relining we guarantee our workmanship for 50 years, and we offer interest-free finance to allow you to get repairs fixed now before disaster strikes.